02 Dec Hydraulic Cylinders—How Do They Work?

Hydraulic cylinders can rightfully be considered a piece of engineering brilliance. Primarily comprised of a steel tube, a rod, and a few mechanical nuts and bolts holding everything in place, they give off immense power.

A power utilized by every crane, tractor, truck, and bulldozer in digging, lifting, pushing, hauling, dumping, and crushing. And while they have helped shape much of the construction world we see, the question remains: how do they really work?

Let’s take a deeper look into the workings of a hydraulic cylinder

What enables cylinders to exert an immense amount of push or pull force is a principle of physics known as pressure. Simply put, pressure refers to the amount of force being applied to an area.

In the case of our hydraulic cylinder, the area refers to the piston. The larger the cylinder’s diameter, the more lift will be generated.

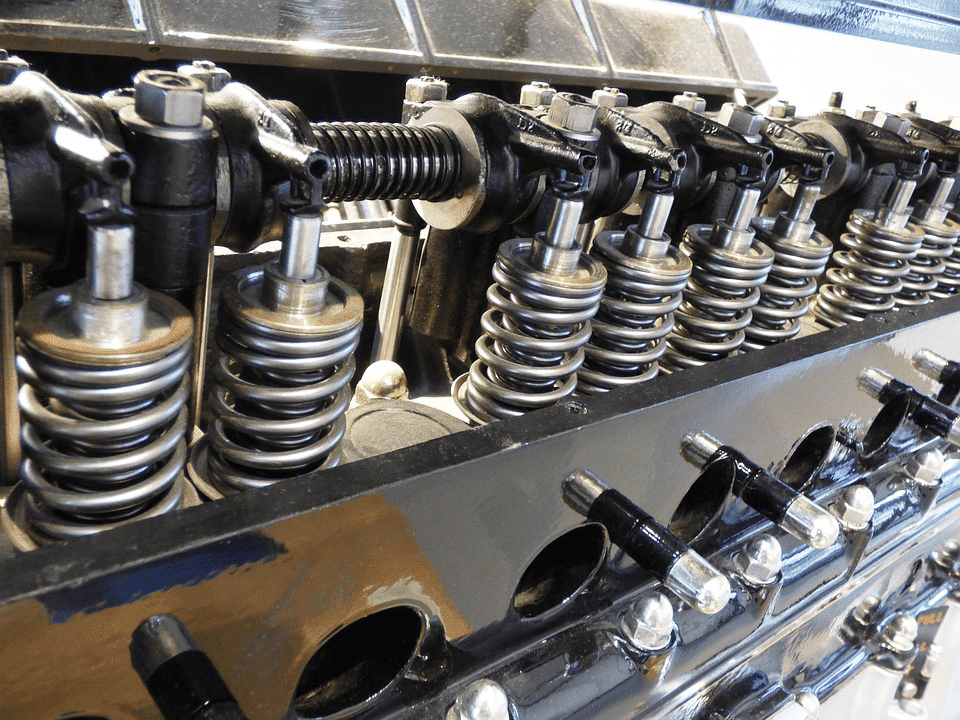

The piston is present inside the cylinder and its diameter is known as a Bore. A piston seal is placed near the middle of the cylinder which prevents the pressure from passing onto the other side. This construction allows the right pressure to be built within the cylinder in order to generate the required force. If the cylinder is unable to lift an object, then most probably the piston seal is worn out.

The piston is attached to the Shaft (or the Rod). The movement of the hydraulics’ fluid causes the rod to pass through the piston with a sizeable nut attached on the other end.

In order to estimate the pulling force of a hydraulic cylinder, the shaft’s surface area has to be deducted from the formula. The shaft is the hardest working component in the entire system. It is the largest single piece of steel and has to withstand the most force. It needs to be incredibly hard (to resist pitting and corrosion), exceptionally strong (to not be bent), and silky smooth (preventing leakage of pressure and fluid). The cylinder’s stroke refers to the maximum distance the shaft can travel from a state of full retraction to full extension.

The cylinder’s “Head” or “Gland” is the part where the shaft retracts and extends through. It also contains the wiper seal and rod seal, both of which prevent the cylinder from getting contaminated.

The cylinder’s “Cap” or “Butt” refers to its base. It is at this point of the cylinder where a wide variety of attachments can be placed. This is generally done with the help of using a PIN-EYE, TANG, CLEVIS or CROSS TUBE.

Maximizing the hydraulic cylinders effectiveness greatly hinges on its production quality and operating life. Contact us now for access to the most technologically advanced hydraulic systems in the industry ensuring your business operates using the very best.