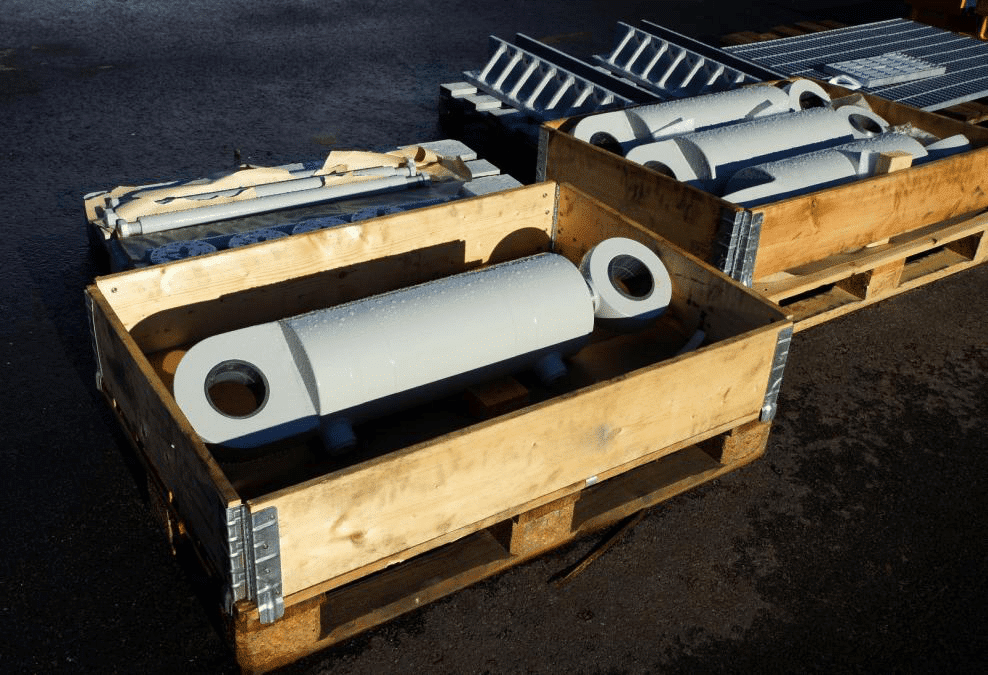

05 Dec MISTAKES TO AVOID WHEN REPAIRING HYDRAULIC CYLINDERS

As is the nature of any machinery that involves moving parts, hydraulic cylinders too inevitably require replacement or repairs. While it may seem like a good idea to service your own machinery, getting your hands dirty without the right information may not only end up damaging your machinery, but also cause you serious injuries in the process. Thankfully, we’re here to impart the wisdom you need to go about the job in the safest and cost-efficient manner possible. So, let’s begin. Here are a few mistakes you should avoid when repairing hydraulic cylinders.

Using the Right Tools

The hydraulic fluid in your cylinders must be allowed to flow freely without any restrictions in order for your machinery to function well. Any leakages which cause the fluid to escape will result in a loss of pressure and drastically reduce your machines maximum efficiency. During repairs, it is imperative that you make use of the right tools. It’s best to avoid tools with sharp edges; this may lead you to accidentally perforate the seals within the cylinder and end up damaging your machine. Go for tools which have blunt edges.

Be Extra Cautious with High-Tension Springs

Large pieces of machinery often rely on hydraulic cylinders with high-tension springs required for proper compression. Repairing or rebuilding hydraulic cylinders requires you to use specialized equipment in order to maintain the spring contraction.

If you are not prepared or lack the necessary skills to work with high-tension springs, you stand at a risk of getting injured or damaging the machine.

It also requires you to understand the tools, sizing of hydraulic seals, and knowledge of high-tension springs.

Ordering Correct Replacement Parts

A common mistake people make is to measure the hydraulic seal size and place orders for a new one based on that. However, seals may expand or contract at different rates when used. It is for this reason that the user manual must always be consulted before placing any orders.

Not Using Lubrication

If your hydraulic cylinders are not well lubricated, it may result in the parts grating together and degrading over time. It will also cause the seals to suffer from higher friction and heat which will cause considerable damage.

Such a problem can prove costly and can be easily avoided by lubricating your cylinders. Make sure to open the intake valve after you have used the lubricating agent otherwise the oil won’t be able to get inside the cylinder.

Repairing your hydraulic cylinders depends on their reliability and sturdiness. Contact us now to get the highest quality hydraulic cylinders in the market making repair jobs few and far in between!