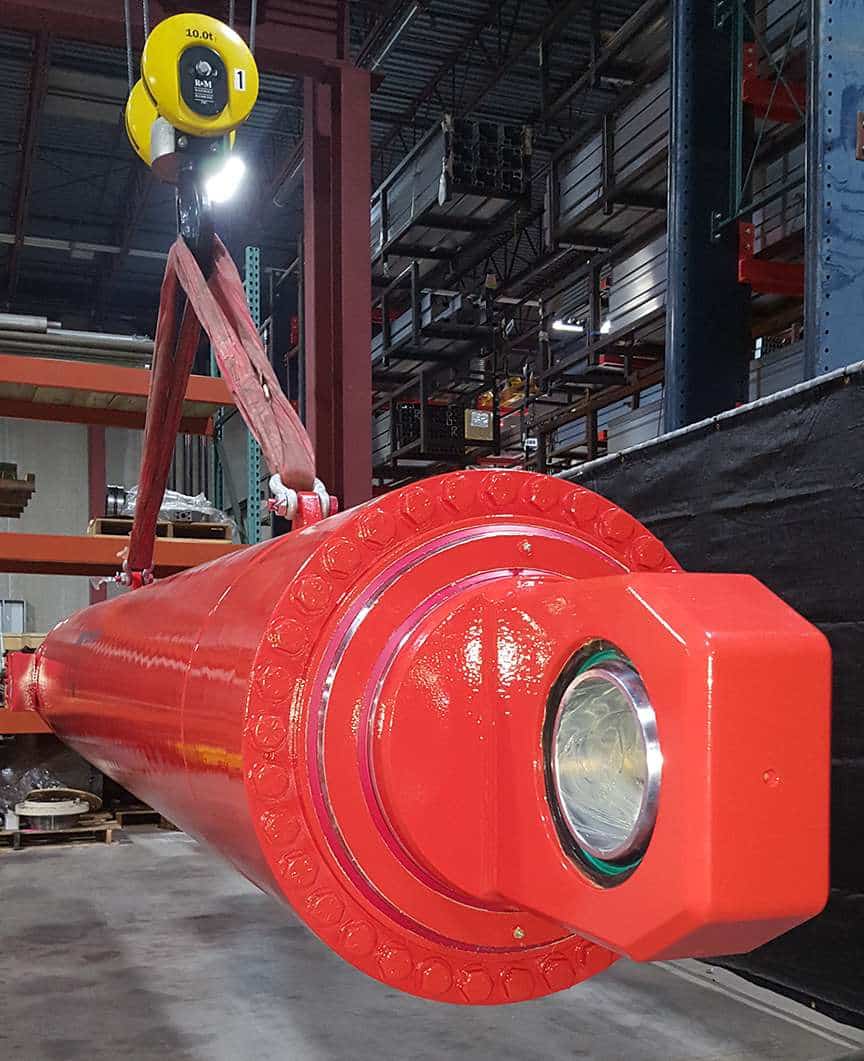

Innovative Hydraulics specializes in the design and manufacturing of large bore hydraulic cylinders

From concept and design to commissioning, we handle every aspect of the design, engineering and manufacturing procedure.

During the design phase, our engineering team works closely with our customers to understand their application and the impact our products can play in competitive advantage and ROI. They pay close attention to the specific conditions of the application, which include operating temperature, loads, environment, working pressure, and safety to ensure efficiencies and outstanding dependability.

Utilizing a range of proven and proprietary design methods, we address issues in the design phase to maximize cylinder performance specifically to our customer’s needs.

Our state-of-the-art manufacturing facility consists of specialized machining and welding equipment, assembly and test lines. To develop quality large bore hydraulic cylinders, we use a wide selection of modeling and testing techniques. This includes FEA analysis, UT weld testing, fluid cleanliness, cushioning, hydrostatic as well as load bearing cylinder actuation tests in horizontal or vertical positions.

From the design phase to years of dependable service in the field, you can rely on Innovative Hydraulics for all of your large bore hydraulic cylinders needs.