30 Nov Features of Custom-Designed Hydraulic Cylinders

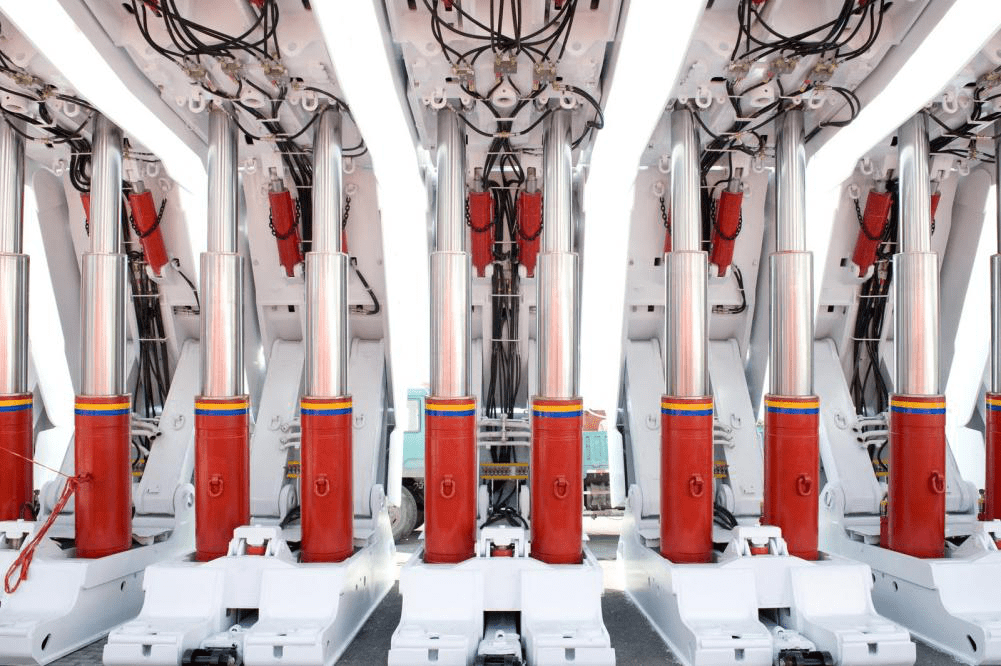

When deciding on the type of cylinder you need for your machines, a wide range of options are available, including but not limited to, single-stage cylinders, double and single acting telescopic cylinders (large and small bore), tie rod cylinders, double end cylinders, mill type cylinders, and accumulators. While each might come close to matching the requirements, there will always be some differences.

For instance, the shaft may be of a different material, the diameter too large, or the bore slightly smaller than what you’re looking for. Such scenarios mean that it’s better to purchase a custom-designed hydraulic cylinder which will be built to fit your needs and match your specifications.

In this blog, we’ll discuss some features of custom-designed hydraulic cylinders that set them apart from the rest.

Standard or “Off-the-Shelf” cylinders are generic in their applications and prove suitable for machinery which is mass-produced and has its specifications based around the functions of a standard cylinder.

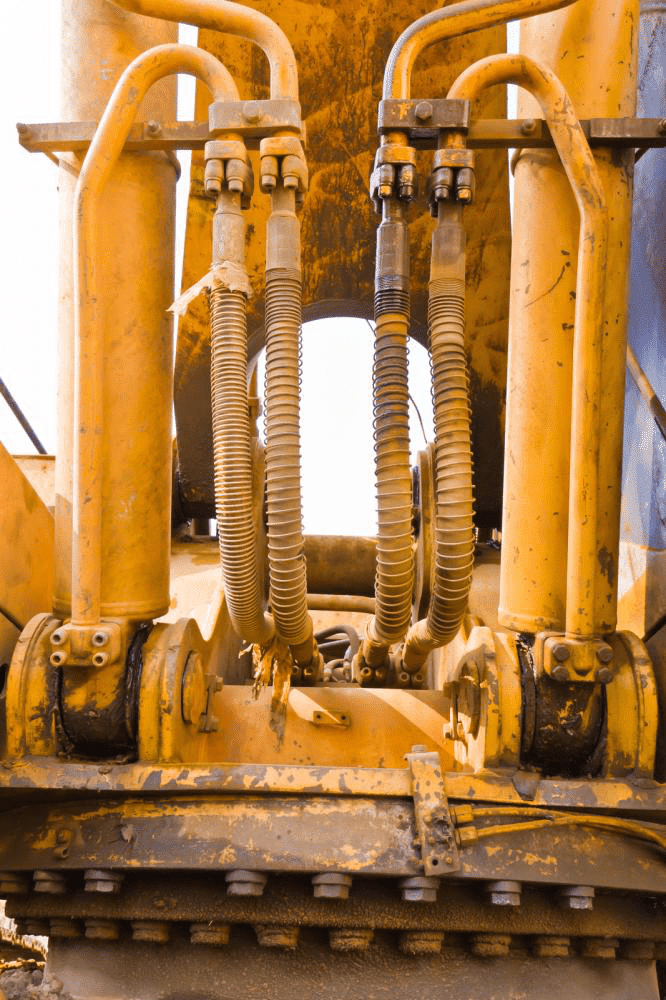

Yet, even such a situation can give rise to complications. For example, integrating a standard cylinder into your design might uncover areas not suitable for your fabrications. This can be in regard to the shape, port size, seal, mounting, design criteria, and even flow.

Custom-design hydraulic cylinders cover all imaginable situations. The piston shaft and other parts are manufactured to the exact diameter and length and are made from the material best suited for the application. Valve manifolds are also incorporated in the cylinder’s body.

Custom-designed cylinders are made to operate under specific conditions such as high temperatures due to the close proximity of furnaces, high pressures while operating deep under the sea or in freezing temperatures and sub-arctic conditions. They have also been known to operate even after remaining in a retracted or extended position for years on end.

Characteristics commonly found in custom-design cylinders include:

- Unusual coatings, finishes, and materials

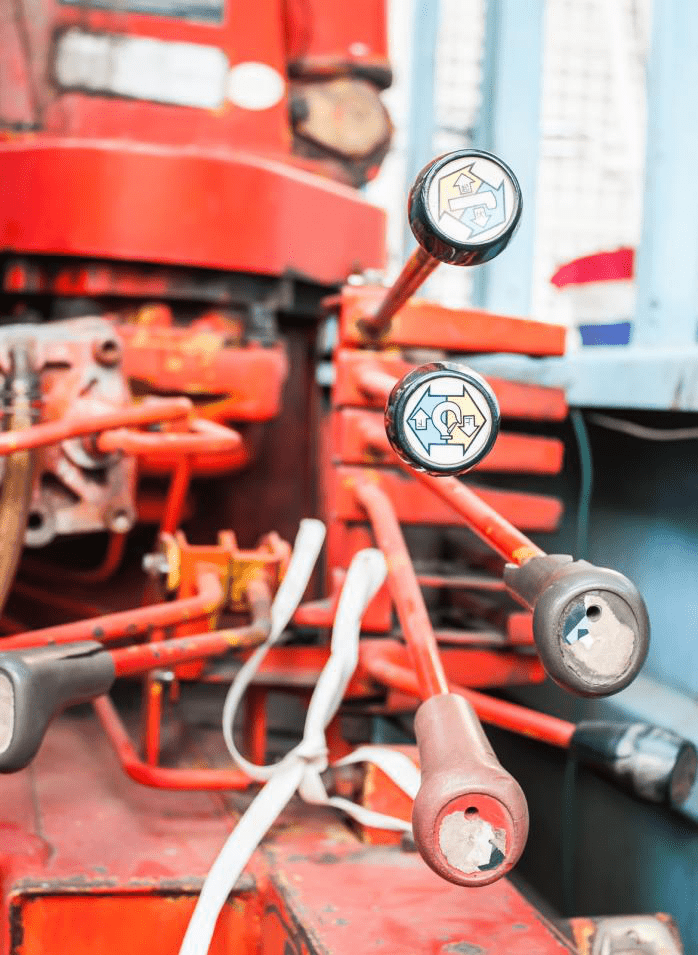

- Unusual pin and port locations

- Extremely large bores and longer strokes

- Compact designs

- Integrated mechanisms such as valves, manifolds, and electronics

As opposed to custom-design cylinders, making use of a standard cylinder which doesn’t synergize well with your machine may complicate the maintenance. It can drive up the cost from machine downtime resulting from required servicing. Other complications which may arise include difficulty in accessing the port locations making service, removal, and installation very time-consuming.

Although the design of your machine is compromised due to customization, it remains the most durable, efficient, and safest choice to compliment and optimize your process. Contact us now to have your custom built hydraulic cylinders delivered to your doorstep!