06 Dec HOW TO REPAIR HYDRAULIC CYLINDERS

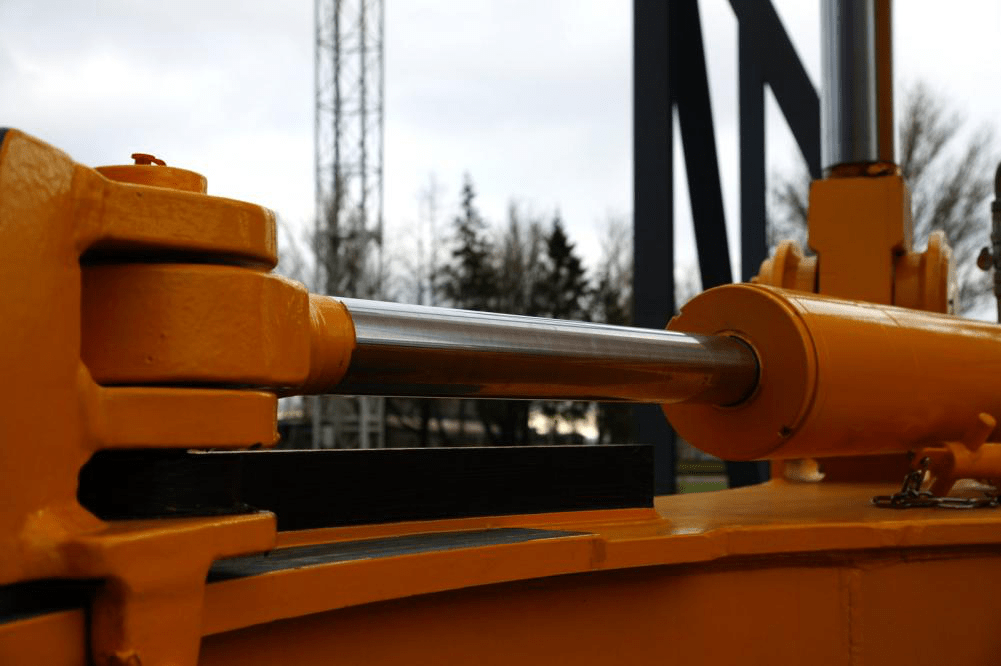

Whether you own a large ranch or are a small-time farmer, chances are, you probably have a truck, tractor or any other machinery that utilizes hydraulic cylinders. These devices are present in most frontend and backhoe loaders and provide the power for lift and steering systems. They are also used for a wide range of operations including cultivation and construction.

But like all pieces of machinery that undergo extensive use and exposure to the elements, the seals in the cylinder will eventually start to leak oil resulting in its maximum efficiency being reduced. In such a scenario, it is imperative to repair the hydraulic cylinders.

Before we begin, it’s important to remember; cylinders are usually classified as heavy machinery and therefore the utmost precaution must be taken to prevent injury or harm. Those seeking to repair hydraulic cylinders must possess some degree of mechanical knowledge.

You must also have the correct rebuilt kit for the job; repairing hydraulic cylinders involves a certain degree of reconstruction. You can do this by identifying the numbers stamped on the end cap.

If the make is of a well-known brand such as John Deere, Case, or any other, simply head on over to the local dealer and purchase the kit you need.

The following Step by step guide shows how to properly go about the repairs:

- The first thing you need to do is ensure all the pressure has been released from the cylinder. Do this by loosening or removing the hydraulic lines present on both ends of the cylinder. You can also unscrew the gland which eliminates the need to disassemble either end from its connections.

- The new tools will allow you to unscrew the gland from its hydraulic cylinder. Usually, a slight bump or tap with a hammer is sufficient enough to loosen the gland. If there is space on the piston shaft, this can be done easily.

- With the gland now removed, you must pull the piston shaft (or rod) from its cylinder. Larger hydraulic cylinders might need some support to keep them upright while you remove the piston rod. A winch can come in handy although it is not required most of the time.

- It is very important that you prevent the piston rod from getting into the dirt or clash against other metallic objects when you pull it out of the cylinder. All parts, including the fine threads found within the cylinder, must be protected from any damage. Haste is waste. Or in this case, a costly bill.

- After the piston rod is free, place its end back into the pin connection and unscrew the bolt holding the piston to the rod. In rare cases, the bolt may require reheating especially if thread locking substances have been utilized in previous rebuilding processes. Careful consideration must be given to not overheat the pistons. Proceed to place all parts back in order. You can take pictures at each step for reference later.

By following these steps, you can get your cylinders working again in no time. However, sometimes, the damage to the cylinders makes the repairs almost impossible. Contact us today to get high-quality, state-of-the-art hydraulic cylinders that will last you for a very, very long time.